- +86 18763116511

- AOLITE Caterpillar Industrial Park, Qingzhou, Shandong, China

- Mon - Sat 8.00 - 18.00Sunday Closed

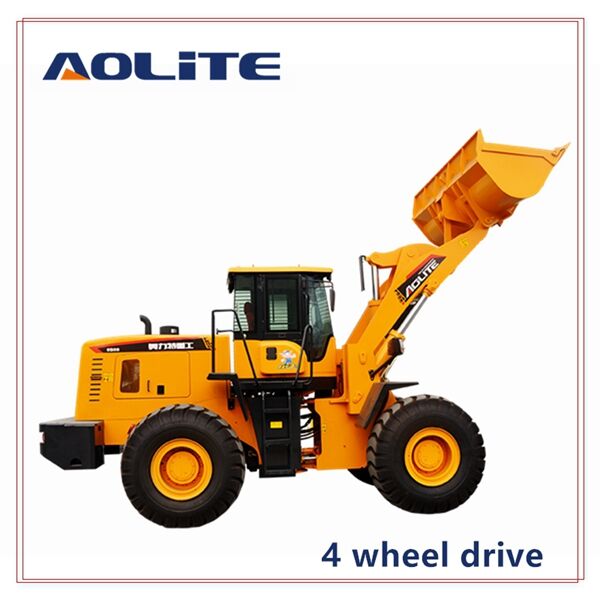

Hydraulic Front End Loader: the effective device Need

A Hydraulic Front End Loader is just a big device with a important purpose: to go really hefty things, like dirt, rocks if not snow. This device is very popular in construction internet sites, farms, as well as backyards. We'll tell you exactly about the Yingnuo Heavy hydraulic front end loader, its benefits, innovation, safety, and many other activities you must know about this.

One of the greatest features of a Hydraulic Front End Loader is that it saves lots of time and effort. This machine can move big lots in just a few minutes, whilst it could take hours and sometimes even days to maneuver exactly the same level of with just human power. Having a Yingnuo Heavy Hydraulic Front End Loader, you may want to keep up with the right level of product in just one destination, letting you become more organized and efficient.

Another great advantage that the hydraulic dumper front end loader is quite versatile. It can be used for many jobs which can be different like searching, carrying, raising and even crushing. This device can be utilized with several types of attachments, like buckets, forks, and grapplers, making it much more efficient for certain jobs.

The Hydraulic Front End Loader is consistently evolving and enhancing. Numerous manufacturers are actually using cutting-edge to generate machines being more effective and green. For example, some new hydraulic front end loaders have a feature called idle management, which means that the machine will immediately turn fully off following a certain quantity of the time, saving gas and reducing air pollution.

Another innovation may be the integration of electronic devices into the device. With brand new Yingnuo Heavy hydraulic front end loader, you can now have real-time details about the machine's performance and maintenance needs, thanks to digital dashboards and sensors. Which means it is possible to optimize the utilization of the equipment and avoid problems that could influence its performance.

Safety is obviously a top priority utilizing any devices. The Hydraulic Front End Loader has several safety features to guard the operator and whoever is working nearby. The most common safety incorporate chair belts, roll-over security, and guarding for moving components to stop entanglement.

In addition, numerous Yingnuo Heavy bucket front end loader have backup cameras that allow the operator to truly have a better view of the environments. This is specially crucial when working in spaces which are tight whenever holding lots that are big block the view.

Utilizing a Yingnuo Heavy Hydraulic Front End Loader may appear intimidating at first, but with some training and guidance, anybody can put it to use safely and effortlessly. Check out actions being fundamental

1. Start the equipment and check out the fluid levels and tire pressure.

2. select the attachment that's right the task.

3. go the equipment to the position that's right making sure the ground is stable and level.

4. utilize the controls to work the equipment, making time for the rate, the angle, and also the load.

5. Keep a afe distance other folks and things which may be in the way.

6. Keep an optical eye on the performance of this machine, and if one thing appears wrong, stop and have it examined.

AOLITE has independent research development capabilities, as well as green innovation capabilities. is a high-tech national company that has provincial innovation lab as well as Applied Technology Research Institute, as well as technical Hydraulic front end loaderfrom Germany Dresden University Technology.

AOLITE insists "customer-centric" and insists making high-quality reliable products. However place a high value to our after-sales Hydraulic front end loader, have set up over 40 service distribution outlets across the globe.

AOLITE factory, built 2005, has area of 80.000 square meters. There two modern Hydraulic front end loaderlines, fully automated single-piece painting line large NUMERICAL Control machining center welding robot and other modern equipment, which includes more than 100 sets.

AOLITE Hydraulic front end loader has ISO9001, CE SGS EAC certifications, well as other. AOLITE has also set up dozens stores for distribution and services as well overseas exhibition warehouses, parts centers other facilities throughout world.