- +86 18763116511

- AOLITE Caterpillar Industrial Park, Qingzhou, Shandong, China

- Mon - Sat 8.00 - 18.00Sunday Closed

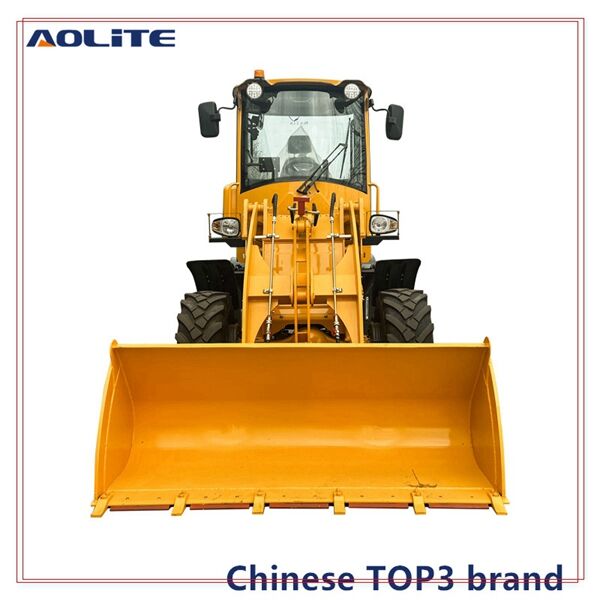

Discover the Benefits of a Front End Loader with Bucket

Do you want heavy-duty machines that may easier make work? the If full case, you will end up surprised because of the benefits of utilizing a Yingnuo Heavy front end loader with bucket. This built device innovative lift, dig, and transport heavy lots of dirt, gravel, or other materials. Moreover, It is really safe to make use of will be of great help in various industries. If you want to learn more about front end loaders, stay tuned and see their features.

Front-end loaders have numerous advantages, including:

Ease of use: A front end loader with bucket is easy to cope with, even if you are not used to machines that are running are heavy. Its simple design and settings help it become an easy task maneuver.

Versatility: Front end loaders works extremely well for several tasks, from digging and excavating to getting rid of snow or debris.

Efficiency: Yingnuo Heavy front end loaders are capable of large lots quickly and efficiently, making them perfect for construction, landscaping, agriculture, and also other companies.

Yingnuo Heavy small front end loaders attended a long way terms of design and innovation. Today’s side end front designed with high level technology, including sensors that monitor the machine’s operation and prevent accidents. Also, they are made to become more efficient and eco-friendly, with features that reduce fuel consumption and emissions.

Safety is really a top concern working any heavy device and Yingnuo Heavy tractor with front end loaders are not any exception. These are typically fashioned with security features such as:

Rollover security systems (ROPS): ROPS give a protective structure keeps the operator safe in the eventuality of a rollover.

Seat belts: Seat belts keep the operator securely within their seat, decreasing the possibility for damage.

Backup alarms: Backup alarms warn people in the specific area that the equipment is reversing, reducing the chance of accidents.

To utilize a Yingnuo Heavy front end loader with bucket, follow these steps:

Examine the machine before use: search for any use or damage and tear that may affect its performance.

Start the gear: Proceed with the steps outlined in the operator’s manual to begin the machine out.

Engage the bucket: utilize the controls to have interaction the bucket and career it where you'll want it.

Gather the load: make use of the bucket to collect the load, being careful to not overload the equipment.

Transport the strain: utilize the settings to move force to its destination.

Unload the load: make use of the bucket to unload force where its needed by you.

AOLITE factory ISO9001, CE SGS EAC certifications, many more. also has set up dozens stores distribution and services, as overseas exhibition Front end loader with bucketfacilities, parts centers other facilities throughout the world.

AOLITE factory, built 2005, has area of 80.000 square meters. There two modern Front end loader with bucketlines, fully automated single-piece painting line large NUMERICAL Control machining center welding robot and other modern equipment, which includes more than 100 sets.

AOLITE an Front end loader with bucket research development capabilities well as the ability to innovate green. is a national high-tech enterprise with provincial innovation laboratory well as one provincial applied technology research institute Technical support by Germany Dresden University Technology.

AOLITE "customer-centric", we insist on reliable, high-quality products. the same time, attach great importance to after-sales Front end loader with bucketwork have set up over 40 distribution and service centers across the globe.